Modernizing a Pump System at a Municipal Water Provider

Location:

Chattanooga

Market:

Municipal Water

Service:

Custom Engineered Skid System

AT A GLANCE

Client: Municipal water provider

Need: Replace an obsolete pump while reusing the existing motor

Target capacity: 13,200 gallons per minute

Constraints: Tight, ~40-ft-deep work zone; aging structure with unknown legacy modifications

Partners: ACME Industrial (mechanical contractor)

Result: A modern pump installation on a custom base and reinforced foundation, aligned, tested, and returned to reliable service

THE CHALLENGE

The plant’s original pump had long been obsolete. A repair was possible—but more expensive and less future-proof than replacement. The catch: a modern pump with the same hydraulics would be wider, which meant the existing baseplate and support weren’t big enough. To control cost and downtime, the existing motor also had to be reused and integrated into the new setup.

Complicating matters, the facility is decades old. Portions of the service floor surrounding the equipment were never intended to carry heavy loads, and the original concrete pier did not extend far enough for a larger footprint. As-built documentation was limited, with embedded steel and inconsistent substrate conditions typical of older industrial sites. These aging-structure realities drove careful investigation and a foundation strategy that could reliably carry modern equipment loads.

OUR APPROACH

Start with certainty. We 3D-scanned the existing pump, piping, and surrounding steel using a Zeiss scanner. That model let us compare the new Ruhrpumpen unit against real-world conditions to confirm fit, access, and alignment paths before any demolition.

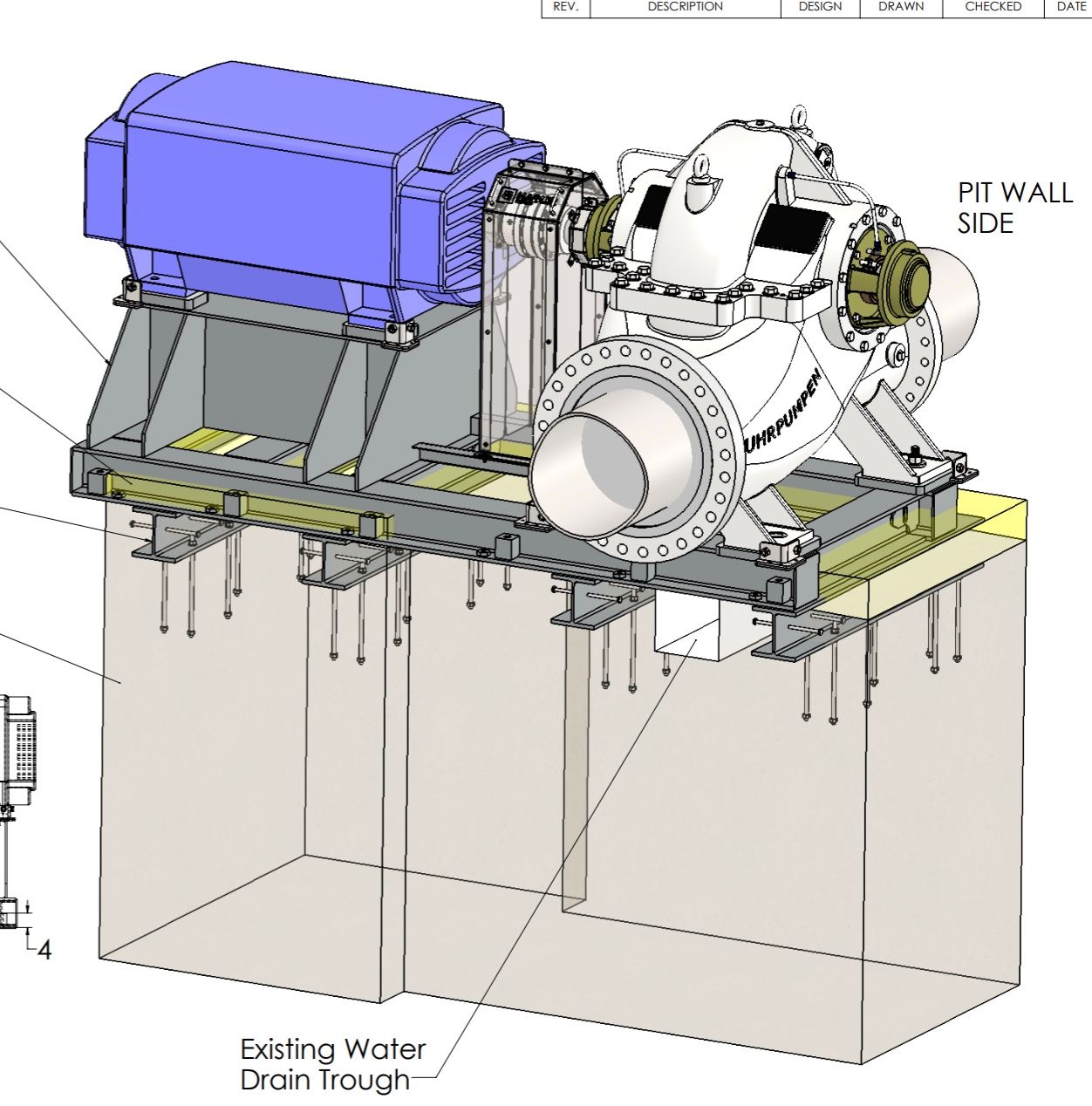

Design for what’s there. Because the wider pump exceeded the old footprint, our engineer designed a custom baseplate around the existing motor centerline and bolt pattern. Subsurface checks (test holes and ground-penetrating radar) confirmed the pier’s limits. We implemented steel sleeper beams tied into the existing pier to safely extend the load path beyond the legacy footprint.

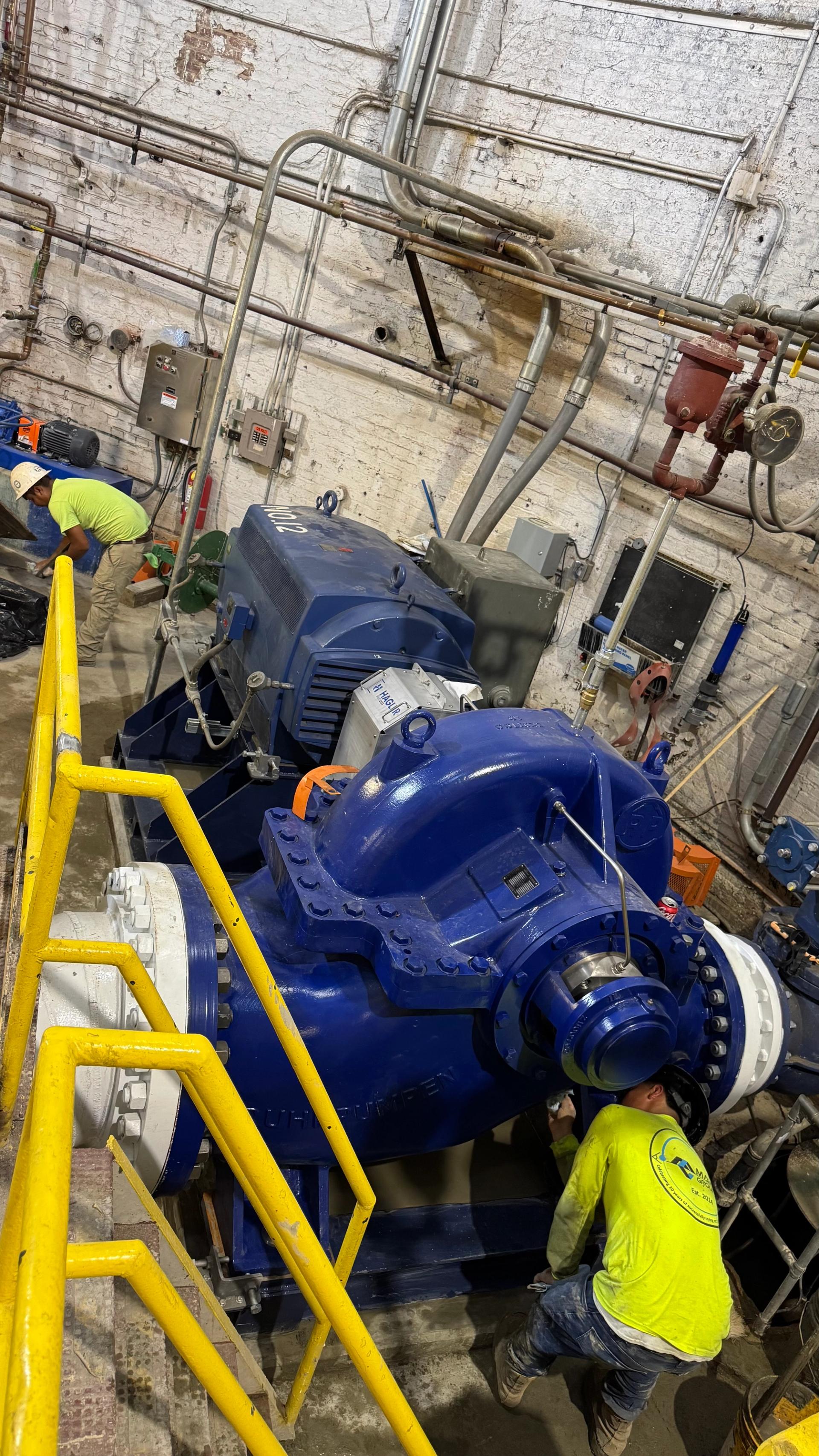

Build with precision. During removal, we found the old baseplate had been partially cast into the pad, so it was segmented and lifted out without damaging the surrounding concrete. We partnered with ACME Industrial to perform mechanical removal/installation and to fabricate custom suction and discharge spool pieces that matched the new geometry. We set the sleeper beams, field-welded the new base, and used precision grouting primarily for vibration damping and stabilization.

Pre-shipment verification. The pump underwent factory performance testing at the OEM prior to shipping to verify hydraulic performance and confirm it met the specified duty.

Pre-startup alignment. After all equipment was installed, we performed final field alignment with an Easy-Laser system immediately before startup.

KEY HURDLES & HOW WE SOLVED THEM

- Aging structure realities

The service floor around the pier was non-structural, the pier footprint was too small for modern equipment, and there were legacy materials/voids that wouldn’t reliably support new anchors.

Fix: Extend the foundation using sleeper beams, tie into the existing pier, and use targeted demolition/coring so new loads bypass weak or non-structural areas.

- Embedded baseplate

The original plate could not be simply unbolted.

Fix: Segment and remove it safely while preserving adjacent concrete, then rebuild the support system to modern tolerances.

- Work zone ~40 feet below grade

With the equipment located deep below grade, logistics and sequencing were inherently more complex.

Fix: Careful planning and staging for personnel, tools, and materials to keep progress steady and safe.

OUTCOME

- Capacity and hydraulics achieved: The selected Ruhrpumpen unit meets the 13,200 gpm requirement while integrating with the existing motor.

- Stronger foundation, smoother operation: Sleeper beams and a custom base create a robust load path; precision grout and laser alignment reduce vibration and maintenance risk.

- Clean fit, minimal disruption: Reality capture and custom spool pieces made the new equipment feel like it was meant to be there.

TOOLS & TECHNIQUES THAT MADE A DIFFERENCE

- Zeiss 3D scanning to eliminate surprises and speed approvals

- Ground-penetrating radar and test coring to verify the pier before cutting concrete

- Custom engineered baseplate + steel sleeper beams to match the modern footprint

- Factory performance testing (pre-shipment) to validate pump performance

- Easy-Laser alignment (pre-startup) for a confident commissioning

WHY IT MATTERS

For a municipal water provider, reliability isn’t optional. This project replaced an obsolete, hard-to-maintain pump with a modern, maintainable unit—without replacing the motor and without major structural rebuilds. The result is a system that delivers the required 13,200 gpm today and positions the plant for dependable service into the future.

SUPPORT

At Hagler Process, we specialize in providing tailored solutions for industrial processing applications, from equipment selection to system optimization. Contact us today at (423) 265-2281 or sales@haglerprocess.com to discuss your needs and discover how we can help improve your operation.