Styles

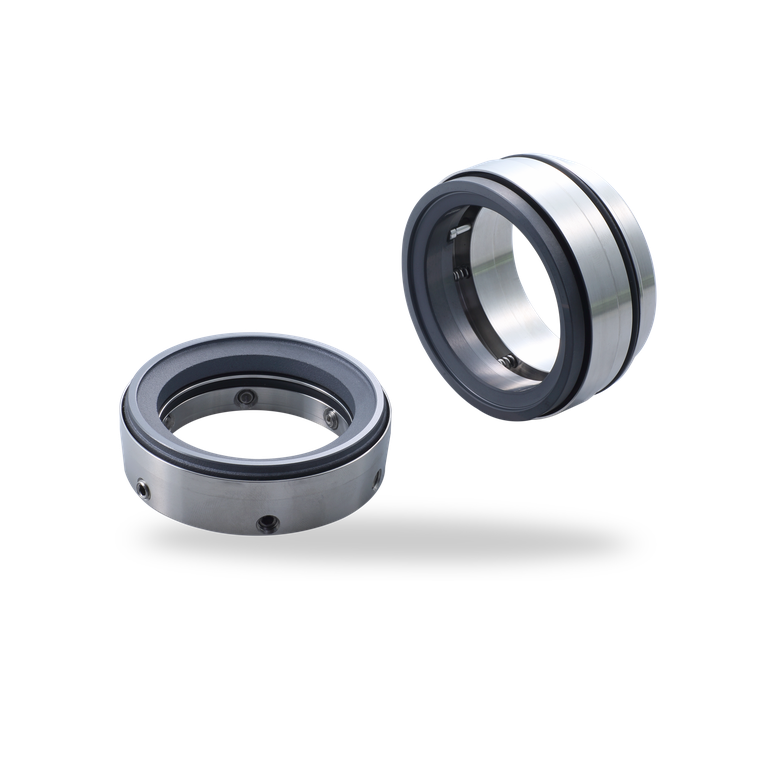

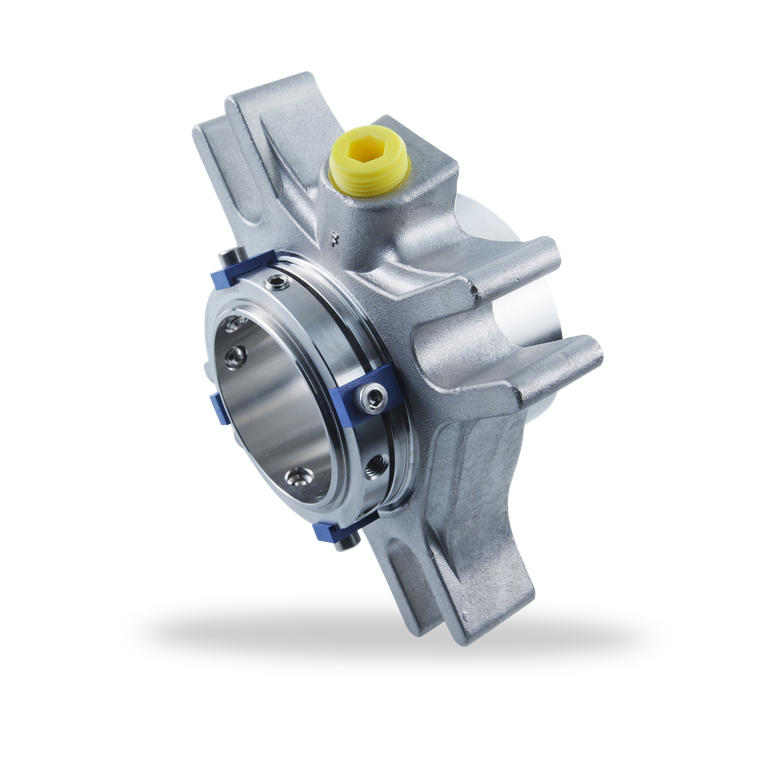

Mechanical Seals

are uniquely designed to provide precise sealing between rotating and stationary parts in machinery, effectively preventing fluid leakage in critical industrial processes under high pressures and temperatures. Their customizability, precision engineering, and leakage prevention capabilities make them indispensable for ensuring efficient and environmentally responsible operations.

Lip Seals

also known as radial shaft seals, are notable for their straightforward design and effectiveness in sealing rotating machinery. Their key characteristics include the ability to create a dynamic barrier around rotating shafts, preventing the entry of contaminants and the loss of lubricants. Lip seals are widely used due to their simplicity, cost-efficiency, and reliability in maintaining equipment integrity while safeguarding against external elements, contributing to prolonged machinery lifespan and reduced maintenance costs.

Packing Seals

commonly referred to as gland packing or simply "packing," are traditional sealing methods used in applications like valves and pumps. They consist of compressible materials, usually braided or twisted, placed within a gland or stuffing box to create a seal. Packing seals are known for their reliability, cost-effectiveness, and ease of maintenance, though they may require occasional adjustment or replacement to prevent leakage.

Markets

- Chemical

- Food & Beverage

- General Industrial

- Heat Transfer

- Pharmaceutical